Here are some of our frequently asked questions about the Build-a-Blade product line. This page will be updated as new questions of general interest arise.

It's easy. Go to our page "Getting started" and choose the method and system

that best suits your needs. We offer

do-it-yourself starter systems with one

chassis and one blade that allow you to grow, as needed, blade and chassis

systems that let you populate all the components yourself, and completely

populated blades systems with the components of your choice, already installed

and tested, with optional customization.

The Build-a-Blade system supports a wide variety of industry standard computing components based on two specific motherboard standards:

1. The Mini-ITX motherboard standard (introduced in 2001 by VIA) for the BB-ITX96 system

2. The new Thin Mini-ITX standard (introduced in 2011 by Intel) for the BB-ITX84 system

In both standards, the horizontal dimensions are 6.7

inches by 6.7 inches [170 millimeters by

170 millimeters] Here is a pictorial drawing from Intel

with mounting hole dimensions:

The Thin Mini ITX standard has a lower vertical height for onboard components, 44mm for standard Mini-ITX versus 25mm for Thin Mini-ITX:

As for other components, you can use any 2.5" disk drive, either standard or solid state drives:

And whatever memory DIMM or SODIMM that the motherboard you choose requires.

For the BB-ITX96 Standard Mini-ITX model blade tray - three 2.5" drives, with stacking rails, six 2.5" drives

It also supports one 3.5" standard drive if needed using an alternate mounting hole scheme.

For the BB-ITX84 Thin Mini-ITX model blade tray - two 2.5" drives, with stacking rails, four 2.5" drives

This depends entirely upon your application and available space. Some pros and cons of each design is shown below to help you decide which system type is best for you.

| Standard Mini-ITX (Model BB-ITX96) | Thin Mini-ITX (Model BB-ITX94) |

| Uses 6 rack units of vertical space, 9 blades | Uses 4 rack units of vertical space, 8 blades |

| Average power consumption for motherboard, 1 drive: 22 watts | Average power consumption for motherboard, 1 drive: 15 watts |

| Wide variety of motherboards available | Limited variety of motherboards available (but more coming) |

| Uses separate DC to DC power converter on the tray | Uses DC to DC power converter on the motherboard itself |

| Support for higher power processors with fan driven heat sinks | Support for higher power processor with thin heat pipe/blower |

| Supports up to six drives for RAID (with optional stacker rails) | Supports up to four drives for RAID (with optional stacker rails) |

Traditional blade systems tend to have two types of power supplies:

Above: Typical power supplies used in blade systems

Above: Build-a-Blade power supply brick with the rack mount power supply tray accessory.

In both cases, our need for open source design and being able to support AC or DC power systems figured into this decision. They main reasons are:

Both the BB-ITX96 and the BB-ITX84 have a built in fan failure alarm and chassis temperature monitoring system. The placement of the control board is inside the front cover door, as seen in the image below:

All fans are monitored for rotation, and if the speed falls, the audible alarm on the control board will sound. Temperature inside the chassis is also monitored via two remote thermistors, and the user can select different temperature alarm levels via jumpers on the control board. When either a fan failure or over-temperature condition is detected, the control board sounds the audible alarm, and flashes the front panel power light. The alarm can be canceled/muted via a push bottom switch inside the front cover door.

Our unique dual-hinged ront door combines eight long-life 56.8 CFM hydro-wave cooling fans and an air filter in one easy to access system. Just two thumscrews give you immediate access to the fans and air filter. The air filter is robust and re-usable, and cleans easily with compressed air or a rinse in water. See the images below.

Fans are secured with four philips screws, it only takes a minute to unplug the fan power cable, remove the screws, replace the fan, and plug the power cable back in and close the door.

This is a built in feature of both the BB-ITX96 and BB-ITX84 systems. Both come ready to run on 12-14VDC power. All that is required is appropriate power connectors/cables to distribute power from your DC power source. See our accessories page for such items that you can order to help with this.

Once you have removed the cables and thumbscrew from the rear of the blade, it only takes about 10 seconds or less to remove a blade and insert a replacement blade. This short period of time won't significantly impact cooling.

There are many blade systems with "hot swap" capability, and while such a feature is easy to implement for standardized motherboards (where you can create a common backplane) it negates the ability offer a wide diversity of motherboards in a single chassis. It also significantly adds to the cost and makes the blade system entiely proprietary, meaning you can't reuse the chassis to upgrade later with off-the-shelf standard components.

Our goal is simplicity combined with long term ROI for the system, our method allows diversity of computing solutions combined with long term upgrade paths.

Yes! This is one of the best features of the system.

For example. Let's say you run a small office and you

need several different machines of differing computing

power:

|

|

|

| Many small business server rooms end up looking like this to accommodate computing diversity. | With Build-a-Blade, your computing technology can be diverse, yet well managed. 18 systems in 12U. |

Each of these diverse computing jobs might need a different level of power and storage. Taking an off the shelf blade system, you can certainly do that, but that often involves overkill in expense and computing power, plus power consumption. With Build-a-Blade, you can tailor each blade to your specific needs at a lower price than a homogenous blade and proprietary server. See our supported motherboard list to get an idea of what you can do.

By placing that computing diversity in a Build-a-Blade system, it makes your servicing easier, your space used much smaller, and your power bill lower. Plus, it gives you an easy upgrade path while retaining your investment. It also makes a "greener" solution since you aren't replacing so much hardware with each upgrade.

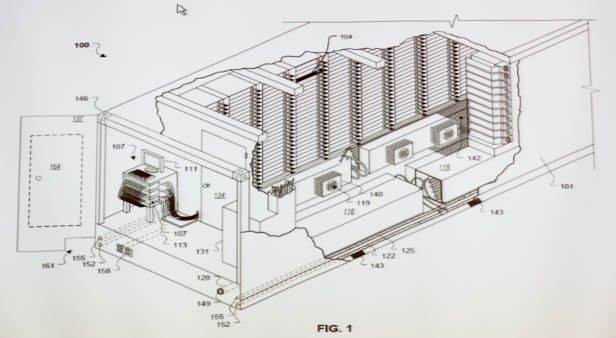

In a lot of ways it is, but our design is more sophisticated at the blade tray scale, but can easily be scaled up. Here's what Google did when they needed blade systems but existing off-the-shelf blade server solutions didn't work for them.

Click to play:

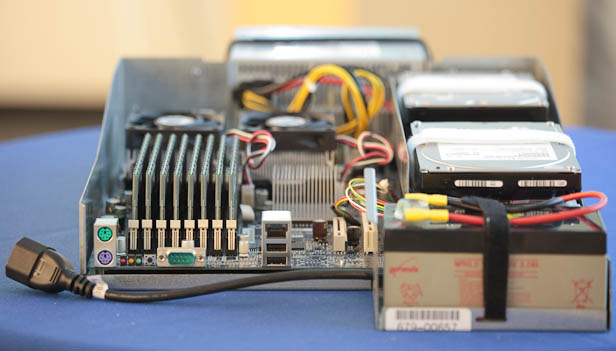

The above video is an overview of the data center at the "container level" while the one below is focused on the blade trays they designed. Compare their blade tray design with ours below.

Here's the CNET report on how Google used off-the-shelf computing components to build server farms in shipping containers.

Google uncloaks once-secret server

A diagram of a Google modular data center

(Credit: Stephen Shankland/CNET)

Google for the first time showed off its server design. (Click to enlarge)

(Credit: Stephen Shankland/CNET)

The rear side of Google's server.

(Credit: Stephen Shankland/CNET)

Our Build-a-blade design uses a similar tray concept, utilizing off-the shelf hardware, but we opted for even lower power than Google did by choosing Mini-ITX rather than Micro-ATX architecture. We also differ in getting the power supply and the motherboard tray separated, which makes cooling easier.

The Build-a-Blade system could easily be adopted by Google (or any other company) for hi-density computing in shipping containers. With the 12 volt DC supply design we embrace, battery backup like Google has done is easy.

Whatever you choose!

The choice is entirely up to you, and depends solely on the motherboard chosen to populate the blade tray. We do offer some pre-configured systems in Windows Server, and on-request, we can install custom operating systems and/or applications as needed. Configuration fees apply.

Some Operating systems we (and some of our users) have tested with our various configurations include:

The limiting factor on most Linux distros are availability of motherboard and peripheral drivers. Be sure to check our supported motherboards at each amnufacturer website to determine if Linux drivers are available.

Many of the low power Intel Atom based motherboard use passive integrated heatsinks for cooling. For more powerful processing applications, larger heatsinks and active fansinks are required. We offer these heatsinks/fans in our configuration system, available at checkout.

Dynatron K199 1U active heatsink/blower fan for Core i3/i5/i7 and Xeon CPUs LGA 1155/1156

Thin Mini-ITX cooling standard via the Intel HTS1155LP Ultra Slim Active Thermal Solution shown below:

The HTS1155LP works well with the Intel DH61AG thin

Mini ITX motherboard and Core i3/i5/i7/Xeon CPU's.

You can add either of these coolers at configuration/ checkout

Other low profile heatsinks will also work with Build-a-Blade systems. For example:

CPU: Conroe-L (TDP 35W), E series Celeron (TDP 65W max), Dual-Core (TDP 65W max), Core 2 Duo (TDP 65W max), Core i3/i5 (TDP 82W max) with good case ventilation